Excavator machines are indispensable equipment in the construction and extractive industries, known for their flexibility and effectiveness. No matter it's excavating, hoisting, or tearing down, grasping the basic components of an excavator is essential for drivers and fans alike. These heavy-duty constructs are engineered to offer superior functionality, and recognizing their components can provide important insight into how they function.

In this discussion of excavator parts, we will dissect the critical parts that constitute these wonders of engineering. From the durable undercarriage to the intricate fluid networks, each part plays a vital role in the complete function of the equipment. By obtaining a more thorough comprehension of these parts, one can recognize the sophistication and potential of excavators, facilitating for better care and functional methods.

Main Components of an Excavator

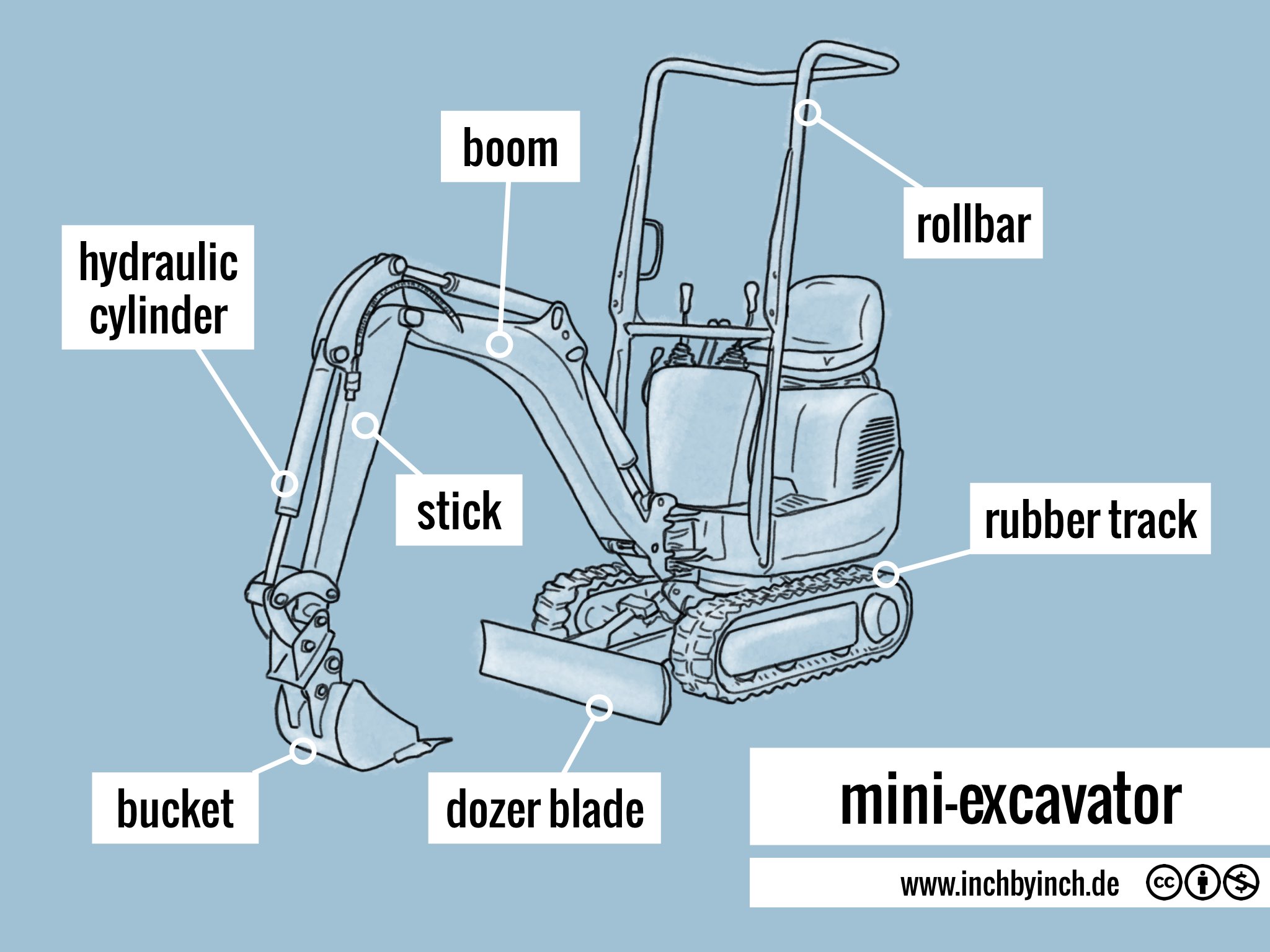

An excavator is composed of several key parts that work together to carry out multiple tasks on building sites. The main components include the arm, arm, and clam shell, which are essential to the excavator's capability to dig, lift, and transport materials. The boom is the long, hydraulic arm that protrudes from the central body of the excavator, offering the reach needed for deep digging operations. The stick connects to the bucket and allows the operator to maneuver it with precision.

The undercarriage is another critical component, providing balance and mobility to the excavator. Typically equipped with tracks, it enables the machine to navigate different terrains while distributing its weight evenly to prevent sinking or tipping. cat parts and other critical systems that support movement and buttress the entire structure.

Additionally, the cab is where the operator controls the excavator. It features a range of instruments and controls that manage the hydraulic systems and ensure accurate operation. The visibility from the cab is designed to give the operator a clear view of the work area, enhancing safety and effectiveness during operation. Understanding these basic parts is crucial for anyone involved in the construction industry or those looking to operate an excavator.

Hydraulics System Introduction

The hydraulics systems is the core of an excavator, responsible for diverse movements and operations. This system pressurized hydraulic fluid to transfer power from the engine to the machine's components. By harnessing the principles of hydraulic technology, an excavator can lift, lower, and turn its attachments with accuracy and strength, making it an essential tool in development and demolition projects.

Main parts of the hydraulics system include the hydraulic fluid pump, valves, cylinders, and hoses. The hydraulic generates fluid pressure, which is distributed through control valves to direct the flow to various cylinders. Each cylinder is engineered to perform specific functions, such as extending the boom, adjusting the arm, or controlling the bucket. The hoses serve as channels, allowing the liquid liquid to move efficiently throughout the setup, ensuring that all parts operate well in unison.

Comprehending the hydraulic systems is crucial for upkeep and diagnosing problems. Routine checks of the fluid amounts and the condition of hoses and links can help avoid failures and prolong the lifespan of the excavator. By making certain that the hydraulics system stays in good condition, operators can achieve maximum performance and achieve the greatest effectiveness of the excavator on the construction site.

Digger Operational Protection Features

Diggers are engineered with different protection attributes to protect drivers and onlookers during use. One of the essential protection elements is the operator's enclosure, which is often equipped with ROPS Shielding Structure (ROPS) and FOPS Protective Structure (FOPS). These systems provide a secure barrier around the driver, lowering the chance of injury in the instance of a rollover or falling debris. Additionally, many excavators have wide visibility through big windows, allowing drivers to ensure awareness of their environment.

Another important protection feature is the incorporation of advanced fluid mechanisms that feature security mechanisms and features. These mechanisms prevent unexpected movement of the digging machine components, ensuring that the arm and bucket do not function unexpectedly while the equipment is stopped. Moreover, various modern excavators come with alarms and notification features that warn the operator to any potential hazards, such as excess load situations or critical maintenance requirements, enhancing overall site security.

Finally, excavators are typically fitted with various safety enhancements such as lights, reflection devices, and reversal cameras. These features enhance visibility during nighttime operations or when operating in tight spaces. Safety education for operators is also essential, as it fosters a atmosphere of safety. By recognizing and employing these protection features, drivers can significantly reduce the risk of accidents on the worksite.